|

|

|

Champion distributes industry

leading Brelko belt cleaning products. Featured

below are the "E" series Belt Scrapers. Contact us today for

orders, quotes and complete product information.

|

|

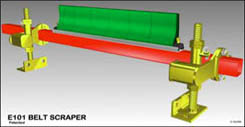

E101 Belt Scraper

APPLICATIONS:

- As a primary scraper

when wet

and sticky materials

are conveyed.

- May be mounted directly

underneath head pulley.

- Can be used singly or

in tandem as a secondary scraper.

- Suitable for all types

of conveyor belts and metal fastening systems.

FEATURES:

- Specially formulated

polymeric blades gives maximum life, and keep the possibility of

damage to belt repairs, splices and metal fasteners to a minimum.

- Patented blade design

ensures optimum combination of flexibilty

and stiffness to adapt to belt profile.

- Patented V base blade

mounting makes blade changing simple, eliminating the need to

remove the scraper from its mountings.

- Brelko torsion mountings

allow the scraper to maintain a constant pressure on the belt and

greatly extend adjustment intervals.

- Also available with

standard adjustable mountings.

|

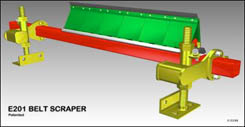

E201 Belt Scraper

APPLICATIONS:

- Universal choice for

most cleaning applications.

- Selection of correct

blade material gives optimum blade life under all operating

conditions and conveyed materials.

FEATURES:

- Unique V base torsion

holder makes blade changing simple eliminating the need to remove

the scraper from its mountings.

- Fully sealed

construction of torsion holder prevents material build up or

ingress into the spring unit.

- Twin arm design of the

torsion holder prevents radial & lateral blade oscillations

and only allows longitudinal blade movement thus ensuring uniform

& constant blade contact with the belt, irrespective of

variations in belt thicknesses and surface conditions.

- Light weight polymeric

material used for the torsion holder ensures ease of handling,

corrosion protection & minimum impact on belt surface after

deflection.

- Torsion holder design

ensures accurate assembly & integral skirts results in cleaner

running scraper.

|

|

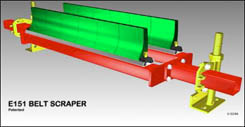

E151 Belt Scraper

APPLICATIONS:

- As a secondary scraper

to ensure maximum removal of wet and fine carryback.

- Specifically designed

for use on belts using metal fastening systems.

- Ideally suited for

conveyors where belts of different thicknesses have been joined

together.

FEATURES:

- Specially formulated

polymeric blades gives maximum life, and keep the possibility of

damage to belt repairs, splices and metal fasteners to a minimum.

- Patented blade design

ensures optimum combination of flexibilty

and stiffness to adapt to belt profile.

- Patented V base blade

mounting makes blade changing simple, eliminating the need to

remove the scraper from its mountings.

- Overlapping double row

configuration ensures optimal removal of carryback.

|

E301 Belt Scraper

APPLICATIONS:

- Specifically designed

to provide optimum coverage of belt surface and therefore maximum

removal of fine and wet materials.

- Selection of correct

blade material gives optimum blade life under all operating

conditions and conveyed materials.

FEATURES:

- Double row three piece

shaft arrangement allows easier

installation.

- Positioning of blades

in an overlapping configuration ensures that any material passing

between the blades of the first row is removed by the second row.

- Unique V base torsion

holder makes blade changing simple eliminating the need to remove

the scraper from its mountings.

- Fully sealed

construction of torsion holder prevents material build up or

ingress into the spring unit.

- Twin arm design of the

torsion holder prevents radial & lateral blade oscillations

and only allows longitudinal blade movement thus ensuring uniform

& constant blade contact with the belt, irrespective of

variations in belt thicknesses and surface conditions.

- Light weight polymeric

material used for the torsion holder ensures ease of handling,

corrosion protection & minimum impact on belt surface after

deflection.

- Torsion holder design

ensures accurate assembly & integral skirts results in cleaner

running scraper.

|

|

|

|